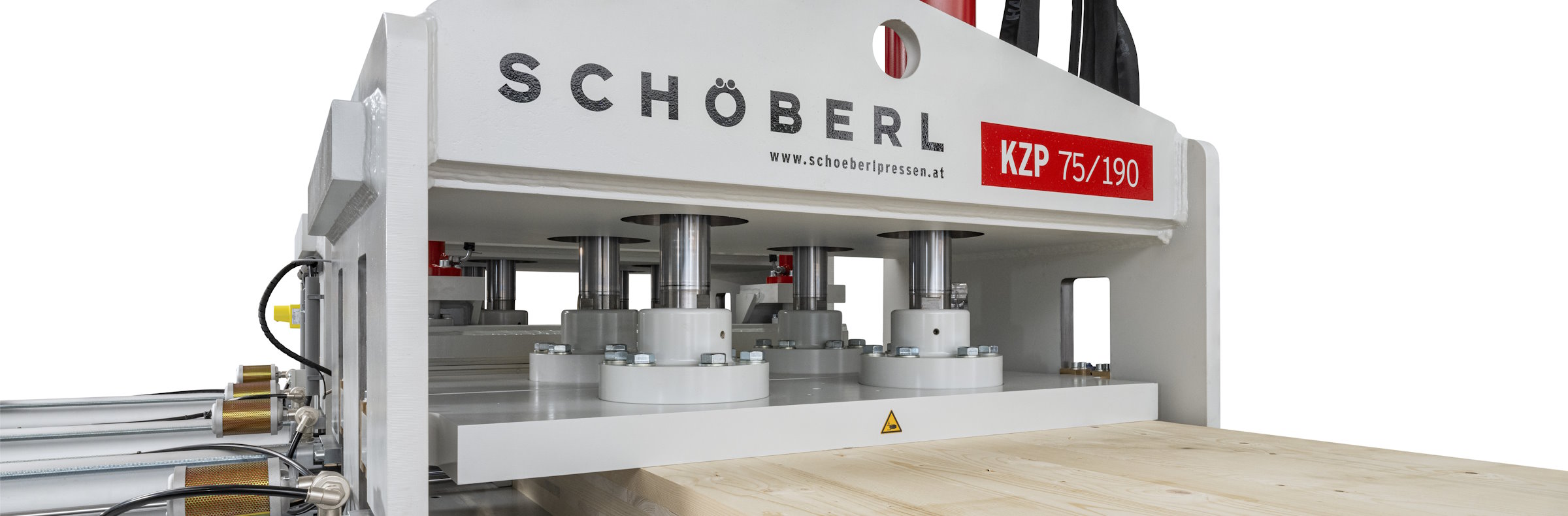

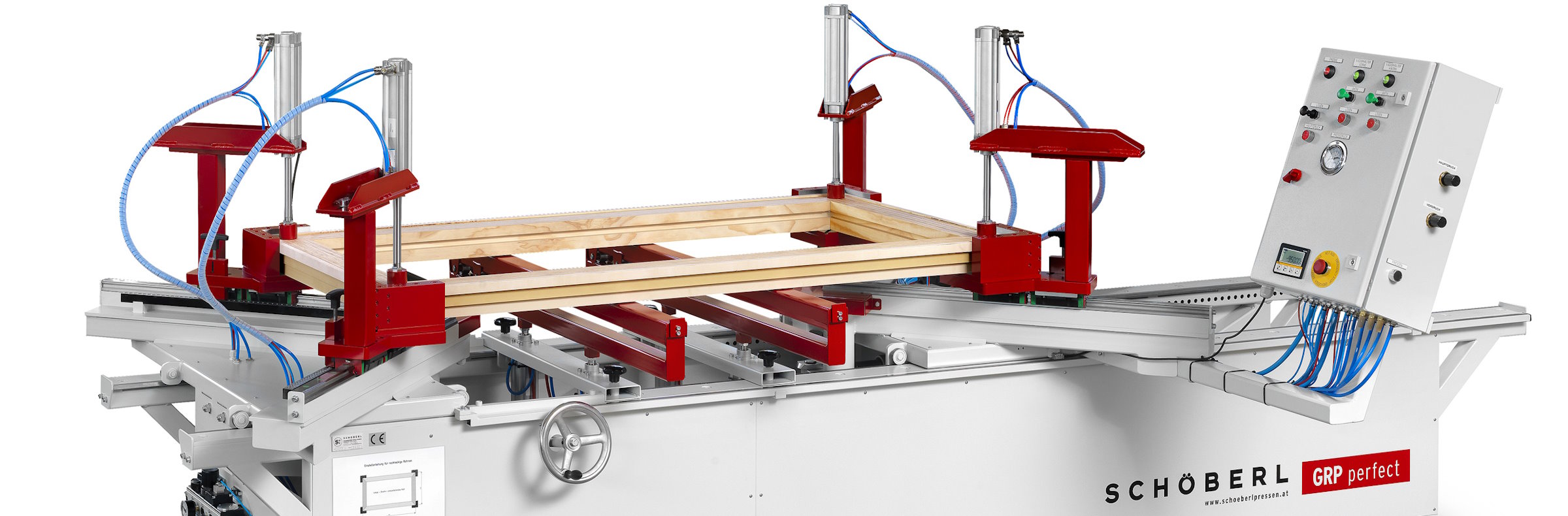

MASSIV.

Ausgelegt für den Dauereinsatz.

Seit 1936 steht der Name Schöberl für robuste Maschinen in hervorragender Qualität. Wir entwickeln, konstruieren und fertigen alle Maschinen in unserem Betrieb in Perg. Neben dem vielfältigen Verleimpressenprogramm bauen wir den Anforderungen unserer Kunden entsprechend Sondermaschinen und bieten für alle Ansprüche optimale Lösungen. Wir sind außerdem in der Lohnfertigung in den Bereichen CNC-Fräsen und Drehen tätig.